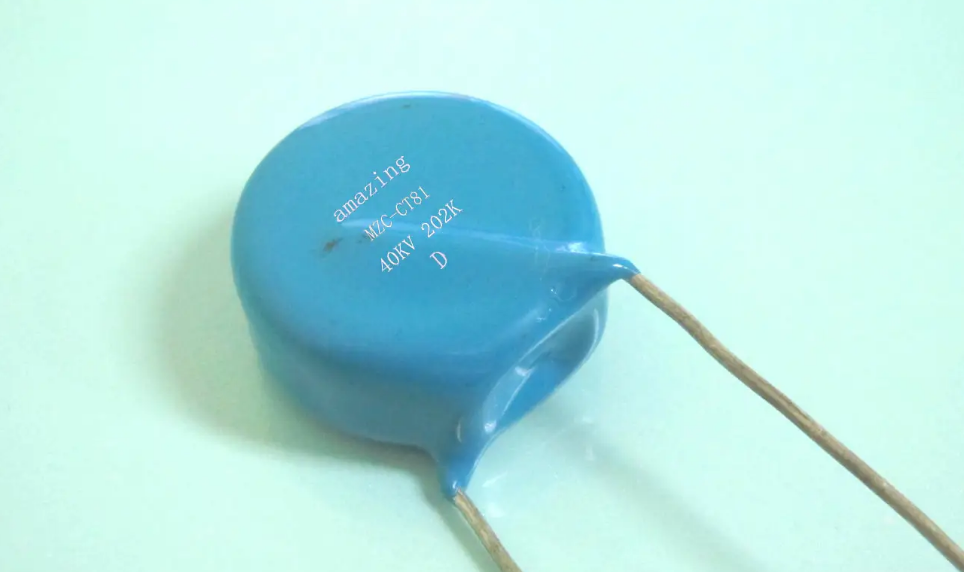

Ceramic dielectric vessel, also known as ceramic capacitor, it takes ceramic as the medium, coated with metal film (generally silver) and sintered at high temperature to form electrode, and then welding lead wire on the electrode, coated with protective enamel on the surface, or coated with epoxy resin and phenolic resin encapsulation, that is, ceramic dielectric vessel.

Ceramic dielectric vessel, also known as ceramic capacitor, it takes ceramic as the medium, coated with metal film (generally silver) and sintered at high temperature to form electrode, and then welding lead wire on the electrode, coated with protective enamel on the surface, or coated with epoxy resin and phenolic resin encapsulation, that is, ceramic dielectric vessel.

Classification of ceramic dielectric vessels

According to the dielectric material can be divided into: high dielectric constant capacitor and low dielectric constant capacitor;

According to the working frequency, it can be divided into: high frequency porcelain dielectric vessel and low frequency porcelain dielectric vessel;

According to the working voltage, it can be divided into: high voltage porcelain dielectric vessel and low voltage porcelain dielectric vessel.

According to the shape of the structure can be divided into: wafer, tube, heart piercing, cylindrical and laminated type.

Ceramic dielectric vessel material

Type I capacitor ceramics: its dielectric constant is generally less than 100, stable electrical performance, basically does not change with the change of temperature, voltage, time, is super stable, low loss capacitor dielectric material, often used in high frequency, uHF, VHF occasions, which requires high stability and reliability.

Type ⅱ capacitor ceramics: its dielectric constant is generally greater than 1000, the electrical performance is relatively stable, suitable for isolation, coupling, bypass and filter circuit and high reliability requirements of medium and low frequency occasions.

Type iii capacitor ceramics: it has a high dielectric constant, widely used in the capacity stability and loss requirements are not high occasions.

The use of ceramic dielectric containers

Class 1: small temperature coefficient, suitable for tuning loops and circuits requiring compensation effects.

Class 2: high dielectric constant, suitable for bypass, coupling, dc isolation and filter circuits.

Type 3: large capacity, small volume, low voltage. Used in filter, bypass and coupling circuits.