Principle of failure analysis of electronic components

Failure analysis of electronic components is to confirm the failure phenomenon of electronic components, identify the failure mode and failure mechanism, and finally confirm the failure cause by means of various test and analysis techniques and analysis procedures. Propose suggestions for improving design and manufacturing processes to prevent repeated failures and improve reliability of components.

1. Component failure

Inductance, resistance, capacitance: cracking, cracking, cracking, parameter change

2. Device/module failure

Diode, triode, LED lamp

3. Integrated circuit failure

DIP package chips, PGA package chips, SOP/SSOP series chips, QFP series chips, BGA package chips

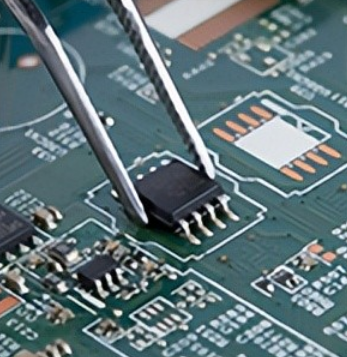

4, PCB&PCBA welding failure

PCB surface bubbling, layering, solder film shedding, blackening, migration oxidation, corrosion, open circuit, short circuit, CAF short-term failure; Plate discoloration, tin surface discoloration, pad discoloration; The insulation performance between holes decreases; Deep hole cracking; Blasting plate etc.

Poor welding of PCBA (ENIG, nickel plating gold, nickel plating gold, OSP, tin-spraying plate); Bad tin on the terminal (pin), foreign body on the surface, electromigration, component shedding, etc

5. DPA analysis

Resistor/capacitor/thermistor/diode, etc

Electronic component reliability verification service

I. Product reliability system solutions

1. Reliability test plan customization

2. Reliability enterprise standard formulation and guidance

3. Life evaluation and estimation

4. Reliability competitive product analysis

5. Product evaluation

6. Device quality is improved

Two, conventional environment and reliability item testing methods

1. Environmental reliability of electronic components

High/low temperature test, temperature and humidity test, alternating humid heat test, hot and cold shock test, rapid temperature change test, salt spray test, low pressure test, high-pressure cooking (HAST) test, CAF test, gas corrosion test, dust and waterproof /IP class, UV/ xenon lamp aging/solar radiation, etc

2. Mechanical reliability of electronic components

Vibration test, impact test, impact test, drop test, triple comprehensive test, packaging and transportation test /ISTA grade, fatigue life test, insertion and withdrawal force test

3, electrical performance reliability

Voltage resistance, breakdown voltage, insulation resistance, surface resistance, volume resistance, dielectric strength, resistivity, conductivity, temperature rise test, etc